Laser Cutting for Pressure-Vessel Heads

Benefit Traditional HyperCNC Solution

Setup Time head< 60 s AI auto-recognition

Accuracy ±2 mm laser repeatability

Material Waste < 2 % optimized nesting

Operator Exposure Class-1 laser safe

Six Competitive Advantages

Vision-AI Recognition

3D cameras map every head in seconds—round, elliptical, or custom—and auto-adjust cutting paths.True Plug-and-Play Modularity

Add extra robot arms, rotary tables, or loading carts as demand grows. Pay only for what you need today.Millisecond-Perfect Laser Drilling

IPG fiber lasers drill 1–50 mm holes at ±0.1 mm tolerance, even on 25 mm stainless steel.Zero-Downtime Maintenance

Predictive sensors schedule service before failures. Remote diagnostics cut MTTR to < 2 h.Universal CAD/CAM Interface

Import STEP, IGES, or SolidWorks files; generate G-code in one click.Global Service Network

24/7 hotline, spare-parts hubs in Houston, Dubai, and Shanghai. Wherever you are, we are.

Title: Modular Laser Cutting & Drilling Line for Pressure-Vessel Heads | HyperCNC

Meta Description (150-160 chars): Boost tank-head production with our modular laser cutting & drilling robot. Zero manual handling, 99.9 % accuracy. Contact HyperCNC for a custom quote today.

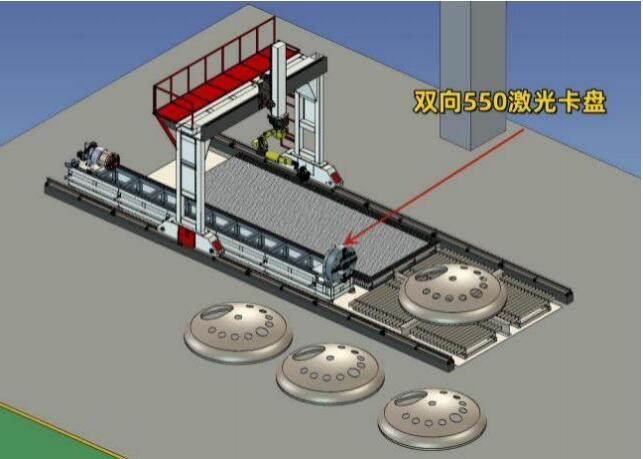

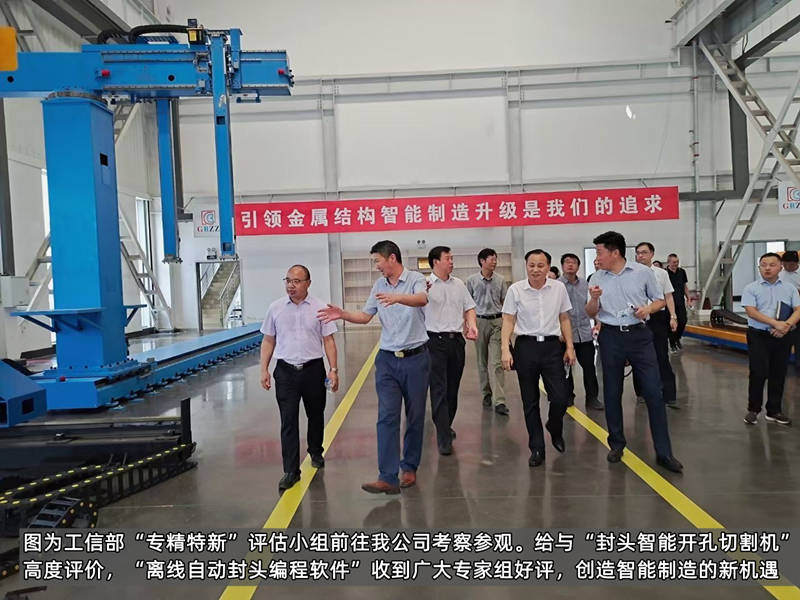

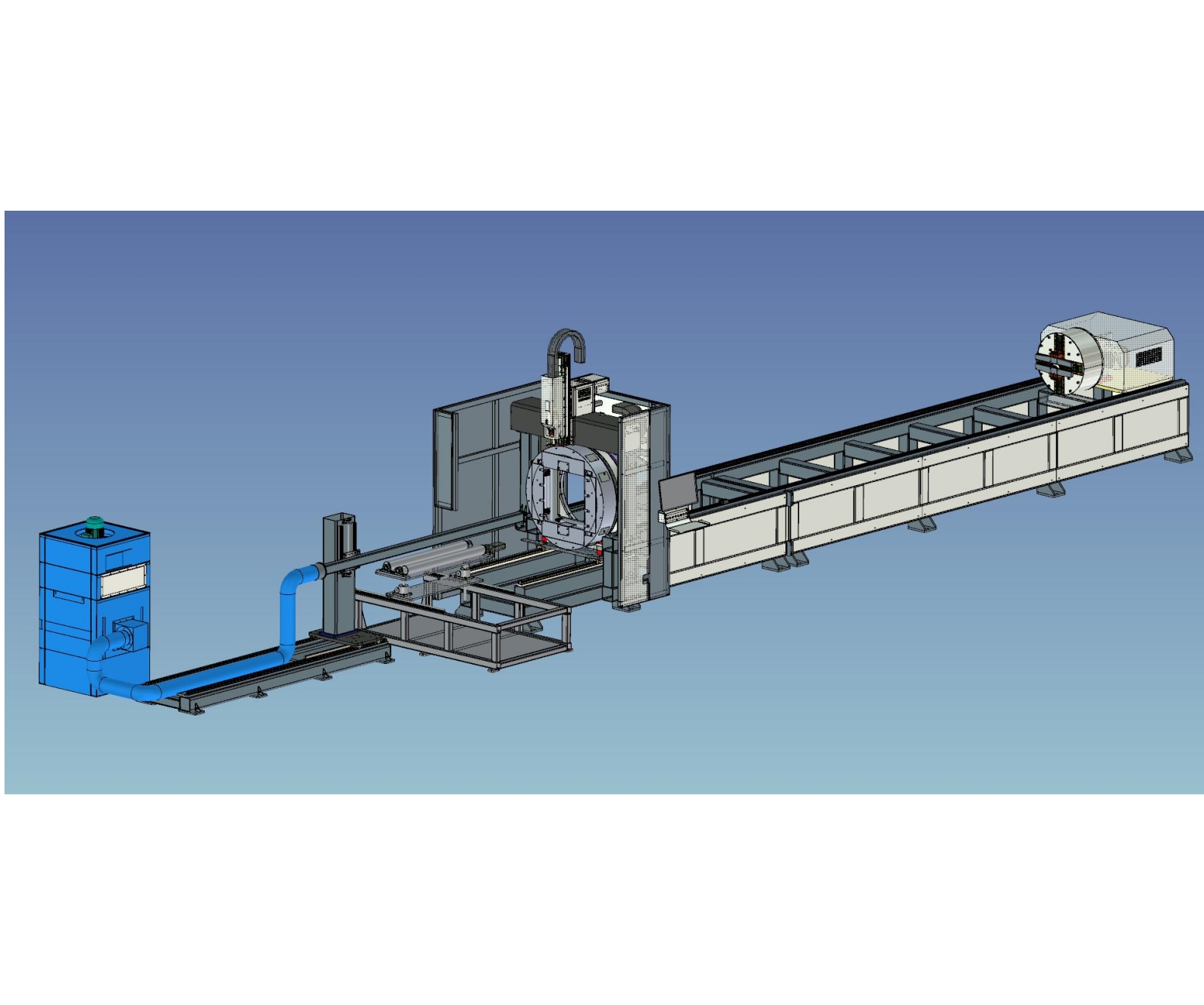

Modular Laser Cutting & Drilling Line for Pressure-Vessel Heads

Automated. Accurate. Always On.

Transform your pressure-vessel head production with the HyperCNC Modular Laser Cutting & Drilling Line—the Industry 4.0 solution that delivers millisecond-precision holes, zero manual handling, and 24/7 uptime.

Why Choose blackhorseCNC?

| Benefit | Traditional Methods | HyperCNC Solution |

|---|---|---|

| Setup Time | 20-40 min per head | < 60 s AI auto-recognition |

| Accuracy | ±2 mm | ±0.1 mm laser repeatability |

| Material Waste | 8-12 % | < 2 % optimized nesting |

| Operator Exposure | High | Fully enclosed, Class-1 laser safe |

Six Competitive Advantages

Vision-AI Recognition

3D cameras map every head in seconds—round, elliptical, or custom—and auto-adjust cutting paths.True Plug-and-Play Modularity

Add extra robot arms, rotary tables, or loading carts as demand grows. Pay only for what you need today.Millisecond-Perfect Laser Drilling

IPG fiber lasers drill 1–50 mm holes at ±0.1 mm tolerance, even on 25 mm stainless steel.Zero-Downtime Maintenance

Predictive sensors schedule service before failures. Remote diagnostics cut MTTR to < 2 h.Universal CAD/CAM Interface

Import STEP, IGES, or SolidWorks files; generate G-code in one click.Global Service Network

24/7 hotline, spare-parts hubs in Houston, Dubai, and Shanghai. Wherever you are, we are.

Industries Served

Oil & Gas: Flare-stack heads, separators

Chemical: Reactor & autoclave heads

Food & Pharma: Sanitary tank ends

Energy: LNG storage domes, boiler drums

INQUIRY

Categories

Latest News

Contact Us

Contact: Mr.Shao

Phone: 0086-17751583908

E-mail: 691043690@qq.com

Whatsapp:8617751583908

Add: shanghai, China TianHe District, GuangZhou Num 899